As the most stringent steel grade in the iron and steel industry, bearing steel is also known as the "king of steel". How to forge bearing steel with "high purity" and "high uniformity", to reduce the oxygen content in the steel to the lowest level, has always been a problem facing my country's iron and steel enterprises.

The powerful spinning technology (PTR) developed by Professor Liu Dong from the School of Materials Science and Technology of Northwestern Polytechnical University and his team break the technological monopoly of foreign giants and solve industry problems.

Solve the carbide content of bearing steel?

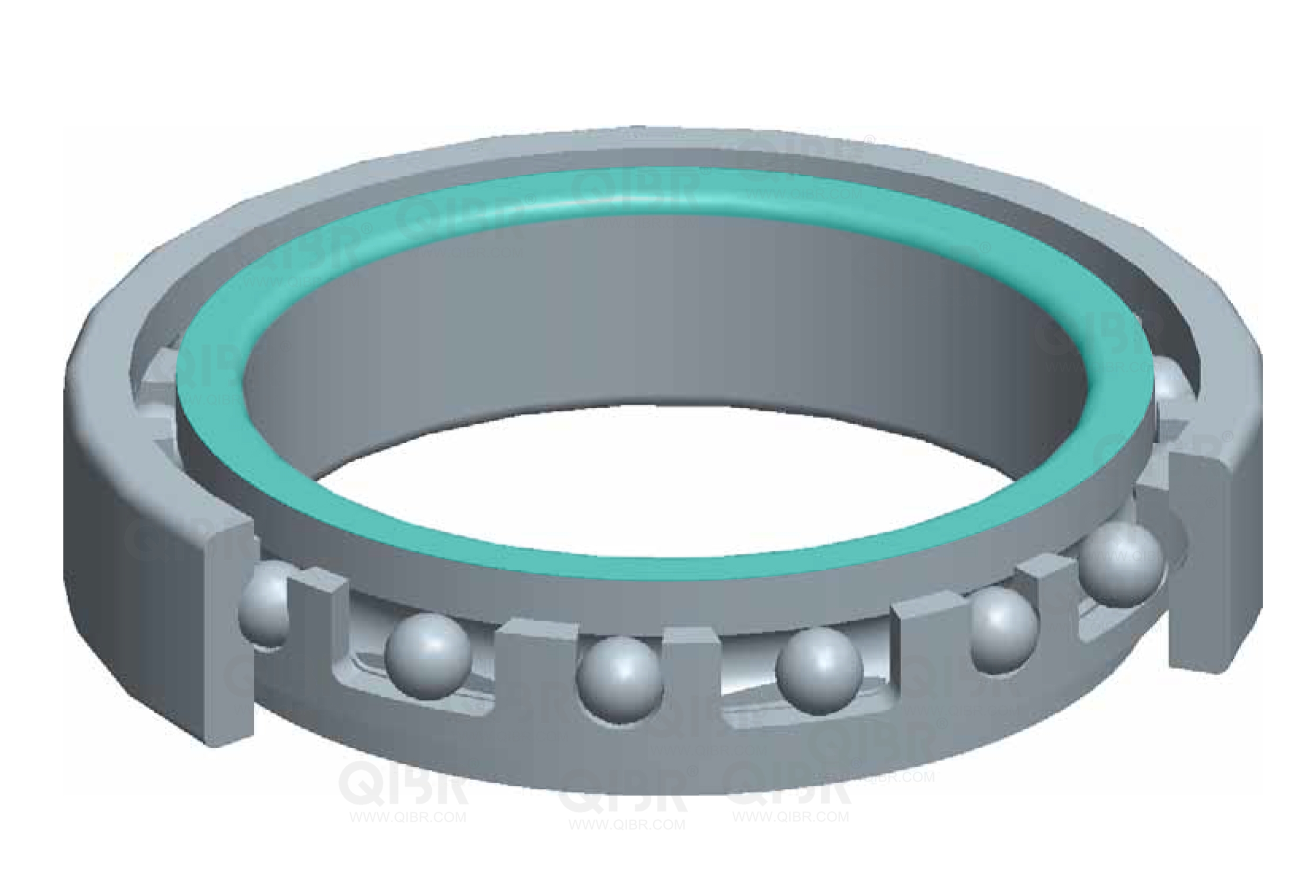

After decades of efforts in our country, technical problems such as oxygen content, inclusions, and segregation have been effectively resolved. The last big problem in the industry, carbide, was overcome by Professor Liu Dong's team.

Bearing steel is high-carbon steel, and its carbon content is relatively high among all steels. If the carbides are unevenly distributed and in large lumps, it will seriously affect the quality. Professor Liu Dong explained, "It's like sprinkling a handful of salt when kneading flour. If the flour is not kneaded evenly, the dough will be salty and hard." "Make the salt evenly distributed in the dough." It is the goal pursued by Professor Liu Dong and his team.

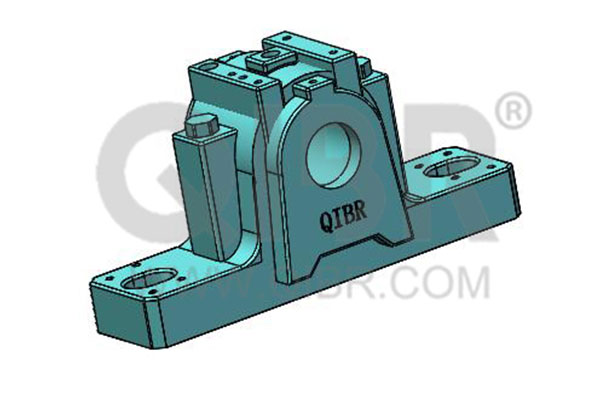

At present, bearing steel modified by PTR technology has been used in many projects. Laboratory data show that with the use of power spinning (PTR) technology, the grain size is refined from the original 50μm to 10μm, and the carbide size is only 10% of the original. For the first time in the past 100 years, increase the hardness of GCr15 bearing steel to above 900HV from 600-700HV, which is at the top level in the world. In addition, the bearing life and reliability have been greatly improved after adopting this technology, and the average life span has reached 26 times the calculated life, and the reliability has reached 99.9%.