As the key parts of industrial robots, the quality and accuracy of industrial robot bearings greatly affect the stability and accuracy of the robot’s work. In the past few years, the company has consulted a large number of related materials and learned about the relevant products and standards of internationally renowned industrial robot-bearing manufacturers. After repeated process tests, on the basis of obtaining a large amount of experimental data, it has formed our own corporate standards. Breakthroughs have been achieved in the design concept, process principles, inspection specifications, and product technical standards of the robot bearing.

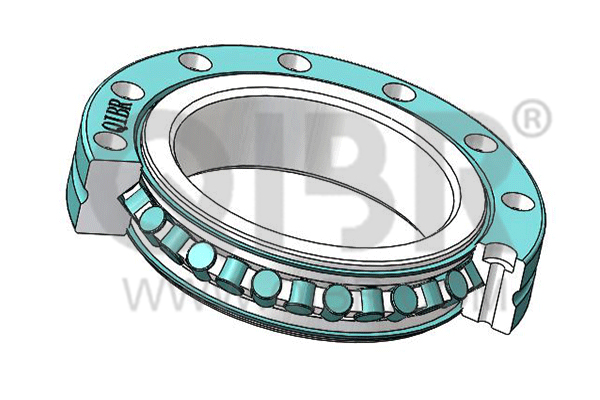

Industrial robot bearings mainly include two categories, one is thin section ball bearings, and the other is cylindrical type cross roller bearings. In addition, there are harmonic reducer bearings, linear bearings, joint bearings, etc., but mainly the first two types of bearings.

The thin section ball bearing is composed of seven open series and five sealed series. There are three types of open series: radial contact type, angular contact type, and four-point contact type.

There are two types of seal series: radial contact type and four-point contact type. The cross-section dimensions of each series of thin section ball bearings are designed as fixed values: 0.1875″×0.1875″, 0.25″×0.25″, 0.3125″×0.3125″, 0.375″X0.375″, 0.50″X0.50″, 0.75″X0.75″ and 1″X1″. In the same series, the cross-section size is the same, it does not change with the increase of the inner diameter size, so it is called a uniform thin section ball bearing. Using thin section ball bearings with large inner holes and small cross-sections, large-diameter hollow shafts can be used instead of small-diameter solid shafts, so that air, light beams, water pipes, cables, etc. can be provided through the hollow shaft space, making the design more Simple.

The use of thin section ball bearings can save space, reduce weight, significantly reduce friction, and provide good rotation accuracy. Make it possible to lighten and miniaturize the host.

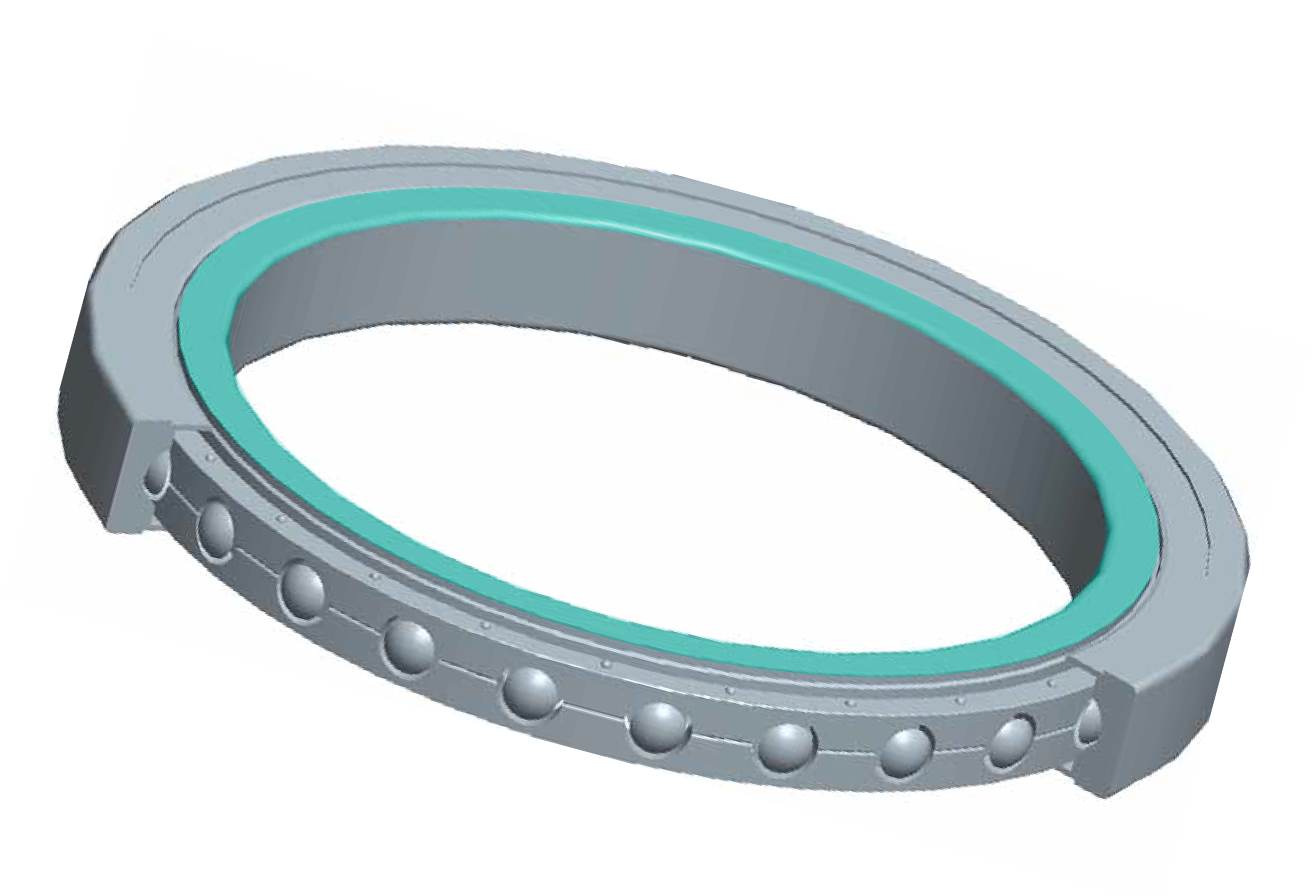

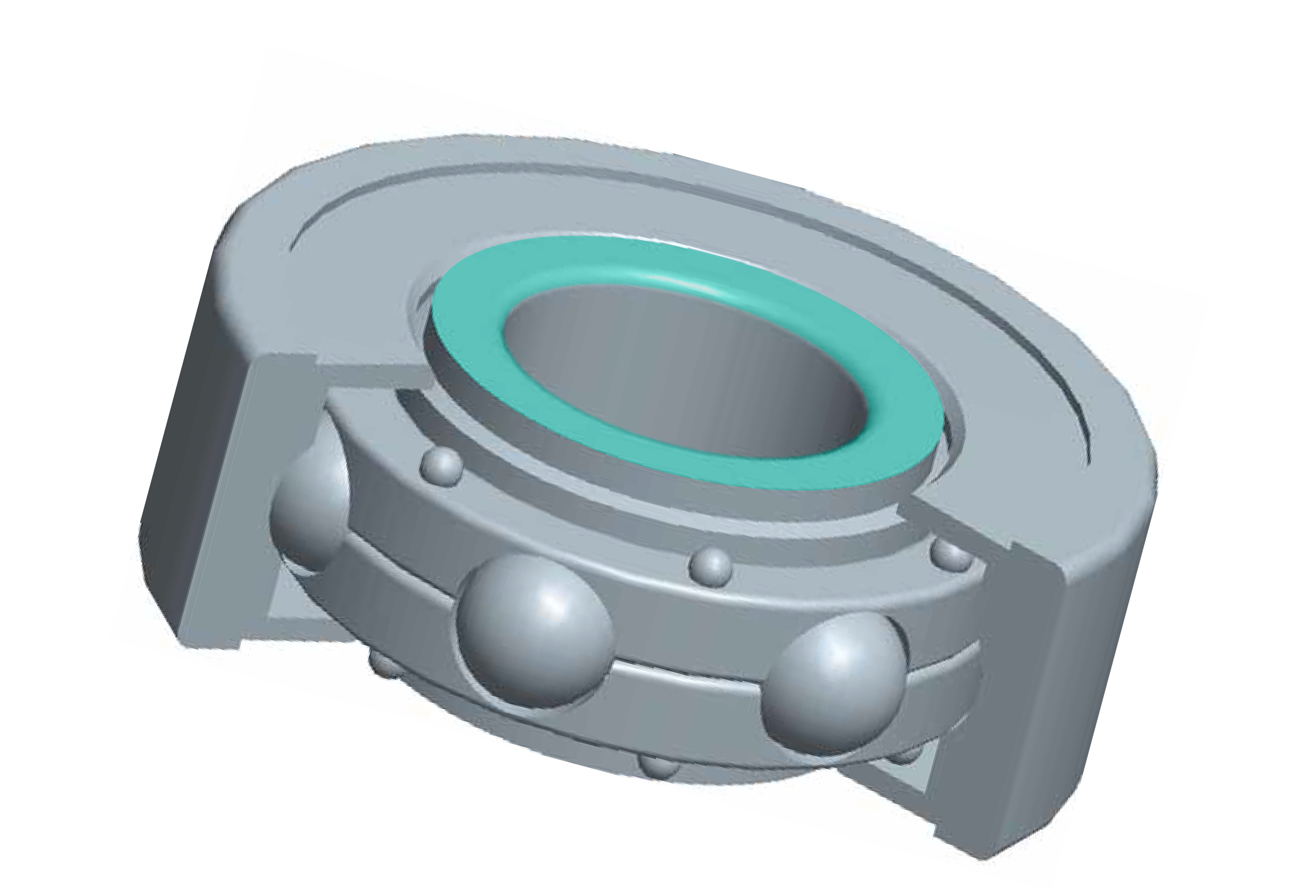

For crossed cylindrical roller bearings, cylindrical rollers are arranged vertically and cross each other in the inner and outer circular raceways of the bearing. A single bearing can bear the combined action of radial force, axial force and overturning moment at the same time. The bearing has a large carrying capacity, good rigidity, high rotation accuracy and easy installation. The main structures of crossed cylindrical roller bearings are: integral type, separated outer ring type and separated inner ring type. For anti-pollution and anti-oil leakage needs, seal rings can be installed on both sides of the bearing.

These two kinds of bearings with their unique light structure and good performance can simplify the design and save space. They are widely used in the fields of robot joints and rotating units, precision turntables and aerospace, semiconductor processing equipment, glass grinders, beverage filling machines, automatic cameras, etc.