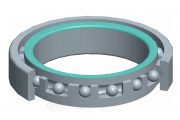

The roller bearing is one of the parts widely used in modern machinery. It relies on the rolling contact between the main components to support the rotating parts. They have the advantages of small starting torque, high rotation accuracy, and convenient use.

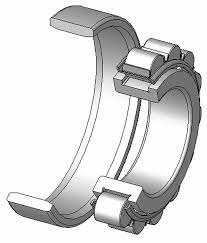

Spherical roller bearings, tapered roller and cylindrical roller bearings, and crossed roller bearings are the main roller bearings

Compared with the ball bearings’ point contact character, roller bearings are in line contact, which is easy to bear large loads and has less deformation after loading.

How to select bearings based on the load direction?

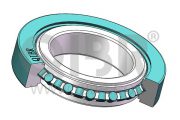

1. For pure axial loads, thrust bearings are generally selected.

2.For larger axial forces, choose thrust roller bearings.

3.For smaller axial forces, choose thrust ball bearings.

4.For pure radial loads, deep groove ball bearings, cylindrical roller bearings or needle bearings are generally used.

5.When bearing a radial load while a small axial load, deep groove ball bearings or tapered roller bearings can be selected

6.When the axial load is large, an angular contact ball with a larger contact angle or tapered roller bearings could be used.

Under normal circumstances, the speed will not have any influence on the selection of bearing type, but when the speed is large, the speed should be considered in the bearing selection.

1.Compared with roller bearings, ball bearings have a higher limit speed, so in the case of high speed, ball bearings are given priority.

2.In the case of the same inner diameter, the smaller the outer diameter, the smaller the rolling elements, the centrifugal force that the rolling elements add to the outer ring roller table will be smaller,it will be more suitable for working at high speeds. Needle roller bearings are more suitable for working at high speeds compared with cylindrical roller bearings.

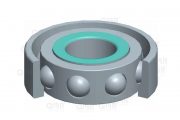

Bearing’s self-aligning performance

When the center line of the shaft does not coincide with the center line of the bearing seat and there is an angular error, or when the shaft is bent or inclined due to force, the axis of the inner and outer rings of the bearing will be deflected. At this time, a self-aligning bearing with a certain degree of self-aligning performance or an outer spherical ball bearing with a seat should be used.

Roller bearings are most sensitive to the deflection of the bearing, and the load carrying capacity of this type of bearing under deflection may be lower than that of ball bearings. Therefore, when the shaft stiffness and the support stiffness of the bearing seat hole are low, or when there is a large deflection moment, the use of this type of bearing should be avoided as much as possible.