Features of Thin-Section Bearinge

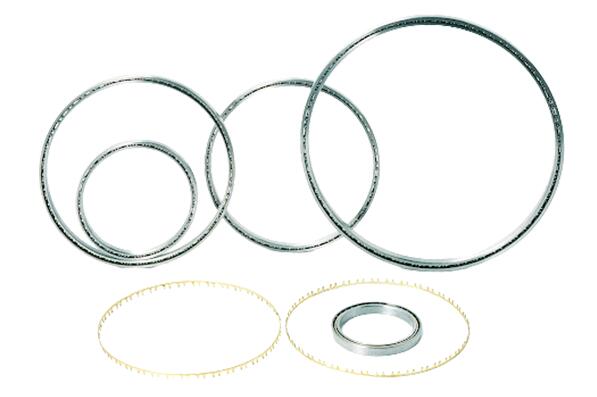

Thin-section bearings are a series of bearings designed with limited widths and thicknesses (cross-sections), and each cross-section has a wide range of bore diameters. Most radial ball bearings are designed as the bore diameter increases, the width and thickness of the bearing change proportionally. Thin-section bearings are designed higher efficiency compared to standard bearing sizes, thereby helping to reduce the overall cost of the system. “The cross-section of thin-section bearings remains the same while the bore diameter increases. The thin-section bearing series consists of 12 main cross-section groups, ranging from 3/16″ to 1″, and bore diameters from 1″ to more than 40”. Thin-section bearings are made of 52100 bearing steel or stainless steel material. They can also be plated with chromium. These sizes can be equipped with seals or shields. Thin-section bearings are also made with one of three different contact methods; radial contact, angular contact and four-point contact. These options and a variety of ball and cage types constitute a variety of parts, even when the cross-section of the thin-section bearing series is limited.

-

-

Thin section angular contact ball bearing

-

-

Thin section deep groove ball bearing

-

-

Thin section four point contact ball bearing

Advantages of Thin-Section Bearing

The cross-section of a thin-section bearing is very small compared to its diameter. This allows it has a smaller design range and lower weight, while achieving high rigidity and running accuracy. Compared with the standardized rolling bearings, the cross-section increased the bearing diameter, and all sizes in a series have the same cross-section, it can achieve a lightweight and compact design.

Applications of Thin-Section Bearing

These bearings are used in many industries, including aerospace, medical imaging, robotics, semiconductors, data storage, machine tools, packaging equipment, covering many different applications. Some interesting and diverse applications include:

Thin section ball bearings are usually used where wires or pipes need to pass through holes in hollow shafts or other arrangements.

Thin-section ball bearings are also used in mechanisms such as universal platforms, and in optical and sighting systems on ships and aircraft. Universal joints are also used for radar and satellite communication equipment, land-based, sea-based, and air-based.

Thin section ball bearings can also be used in all types of work holding devices, such as turntables, indexing and turntables.

They are also the perfect solution for smooth movements in articulated parts such as the elbow of a robot arm or other articulated joints.

Thin section ball bearings were developed for applications where space limitations are of the utmost importance, which require the use of smaller balls due to the reduced cross-section. This is to a certain extent at the expense of load capacity, however, these bearings can still withstand medium radial thrust or combined loads.