Many modern large-scale engineering machinery, such as asphalt mixing equipment, stabilized soil mixing equipment, and combined crushers, are large in scale, and the mass of each part is tens to hundreds of tons, and most of the construction machinery is in sand, gravel, and rainwater. Working in harsh environments such as wind and snow, its technical status will inevitably decline faster than other machinery. The coordination of parts will show varying degrees of looseness, wear, corrosion and scaling. The nature of the mating of each connection and the mutual position of the parts Relations and coordination of institutional work will be affected to varying degrees, resulting in a decline in performance indicators such as power, economy, and reliability, and even machine accidents. Therefore, attention must be paid to the selection and technical maintenance of parts and components in construction machinery, especially bearings. A high-quality bearing can increase the working life of construction machinery and improve work efficiency, thereby improving economic benefits.

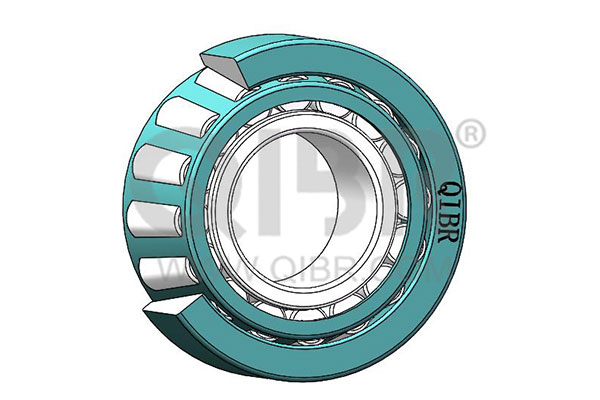

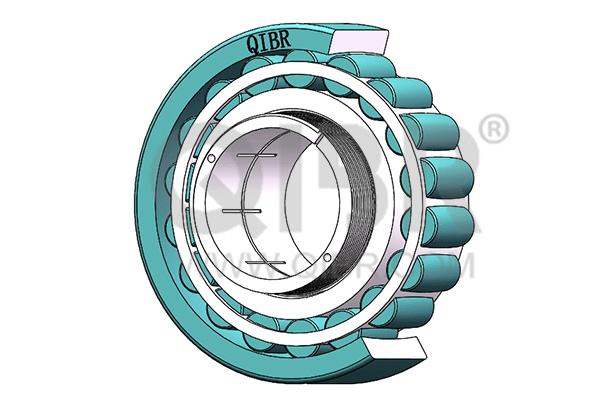

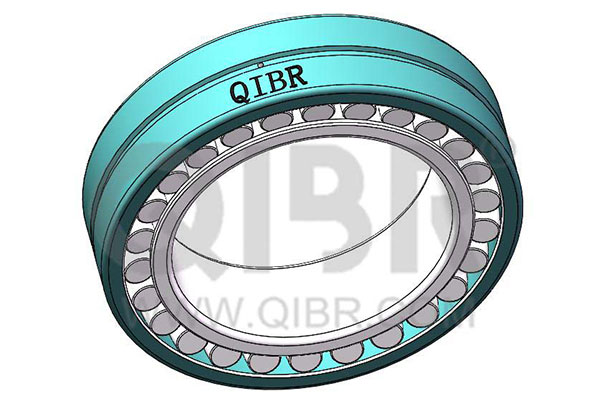

QIBR has the ability to design and manufacture bearings of different structures and sizes according to the user’s working conditions and equipment requirements, all of which have the advantages of large load capacity, high performance, and long service life, which can ensure the smooth operation of the equipment in harsh environments.

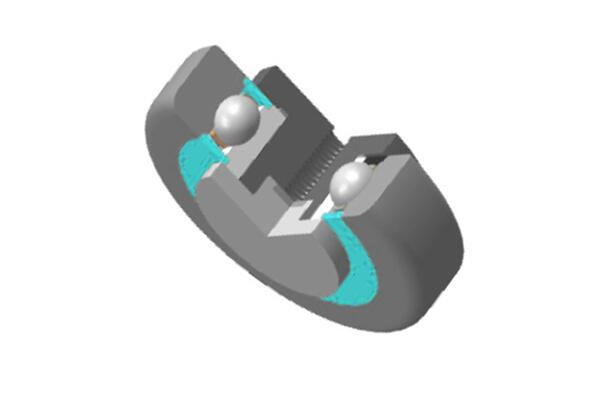

QIBR provides bearing types for construction machinery and equipment: slewing bearings, deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, CARB toroidal roller bearings, spherical roller bearings, tapered roller bearings, etc.

-

Needle roller bearing

-

-