Features of Slewing Bearings

The slewing ring includes an inner ring and an outer ring, one of which usually contains a gear. Together with the connecting holes on the two rings, they achieve optimized power transmission through simple and quick connections between adjacent machine parts. The bearing raceways are designed together with rolling elements and cages or spacers to withstand loads in any direction, alone or in combination.

Types of Slewing Bearings

-

-

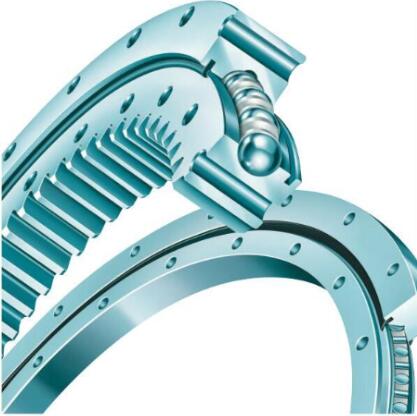

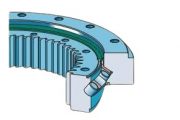

Single row four point slewing bearing

-

-

Two row four point slewing bearing

-

-

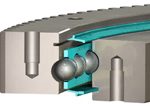

Two row ball slewing bearing

-

-

Combined ball roller slewing bearing

-

-

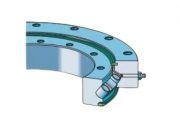

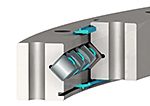

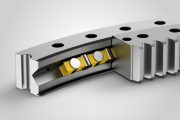

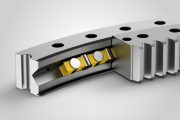

Cross roller slewing bearing

-

-

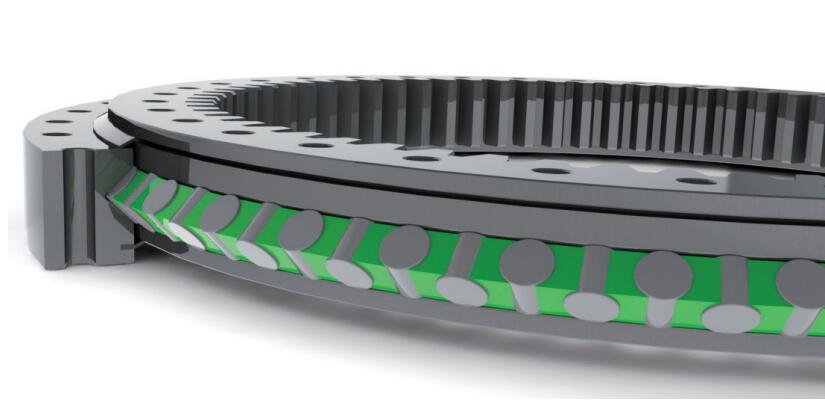

Three row roller slewing bearing

How to Choose the Suitable Slewing Bearings

The main reason for the failure of slewing bearing processing is the unreasonable selection in the early stage and improper maintenance in the later stage. How to make a reasonable product choice, usually we consider the following aspects: the working conditions of the slewing ring, performance requirements (lifetime, accuracy requirements, speed, lubrication), etc., a reasonable choice can eliminate many potential hazards. The following information can help you choose the right slewing bearing.

Single-row four-point contact slewing bearing

This type of slewing bearing is widely used in the market, which with a compact internal structure. Mainly used for axial load conditions and large overturning moments.

Double row slewing bearing

This type of slewing bearing is composed of double rows of rolling elements, which can bear radial force, axial force and overturning load moment at the same time. The requirements for installation accuracy and base deformation are not high. It is not recommended for use in high-precision equipment.

Three-row roller slewing bearing

This type of slewing bearing can withstand larger loads. Compared with the above two types of slewing bearings, when the center distance of the raceway is the same, the unique internal structure makes the three-row roller structure have the strongest load-bearing capacity, but due to the sliding phenomenon when the rollers roll, so It has large running resistance and high processing requirements for raceways and rollers. The base has a certain rigidity during installation, and it is widely used in occasions with large bearing and small deformation rate.

Cross roller slewing bearing

Because its structural section is straight, it can withstand radial force, axial force and overturning moment. Suitable for occasions with high precision requirements. According to customer requirements, the assembly gap can be adjusted to a negative gap.