First, we must pay attention to the installation. If the installation is not correct, it is very common to have problems when the bearing is running. This will have a serious impact on the accuracy and performance of the bearing. It will reduce its lifespan, so when installing, you must abide by the norms of the operation, you must pay attention when you should clean it, it needs to be cleaned, do not wash it roughly, and check whether these parts, dimensions, etc. need attention.

Second, after installation, it is necessary to re-check. What is needed is to check whether the bearing will work, whether it is suitable or not, and the main point is that it provides lubrication, etc., not too little, but don’t overdo it either.

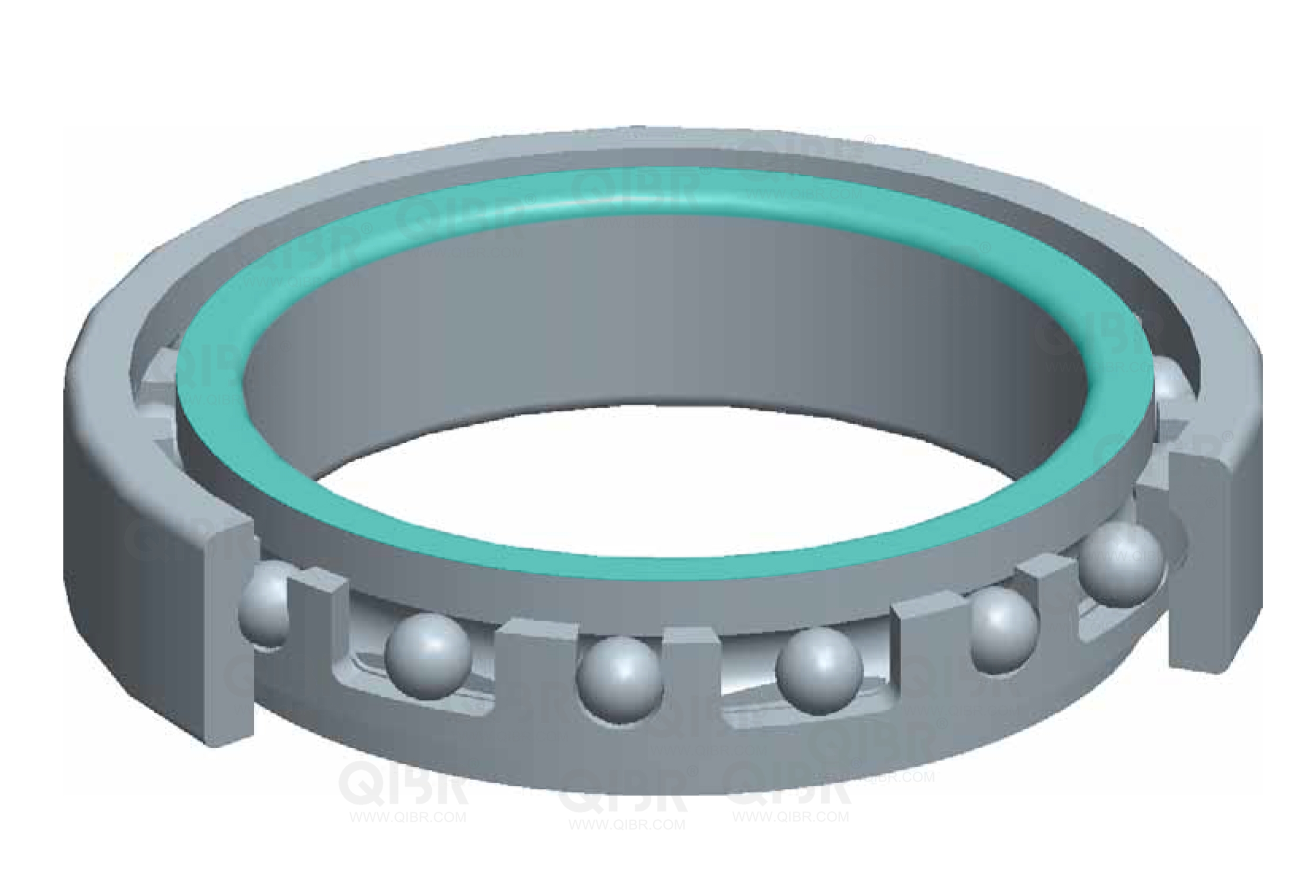

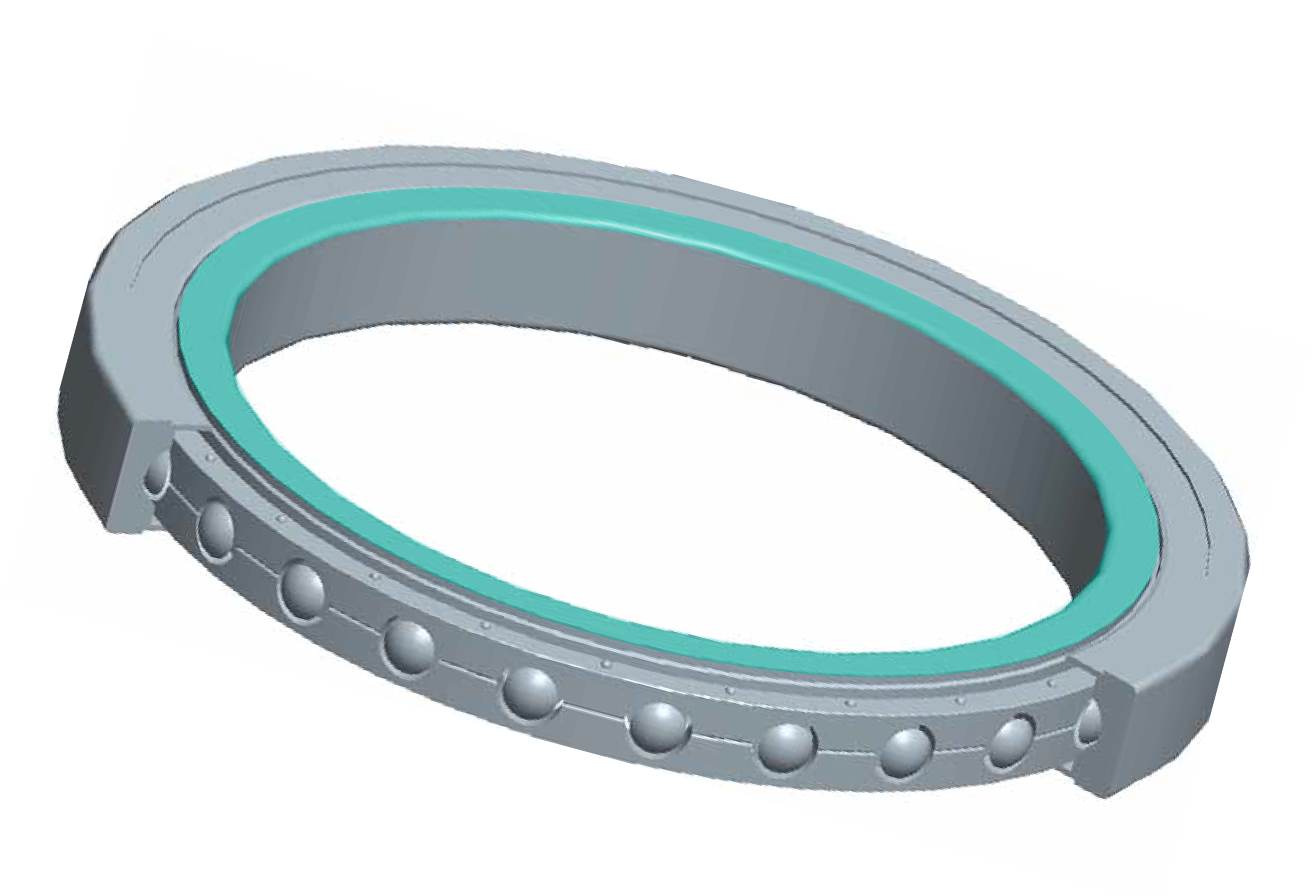

Third, spherical roller bearing needs to be aligned and straightened. If it is not done in this way, it will be subjected to excessive load, friction type, and vibration, which will reduce the life of the bearing. It will also have a destructive effect on other data.

Contamination can also cause premature damage to the bearing. Contamination means that sand, dust, metal chips, etc. enter the inside of the bearing. The main reasons include: opening the bearing packaging prematurely before use; the working environment of the device is not clean and causing pollution; the working environment of the bearing is not clean, and the working medium is polluted.

Suggestion: It is better not to unpack the bearing before use; keep the device environment clean when installing, and stop cleaning the bearing once operates;