The development of modern industrial robots tends to be lightweight. Bearings must be installed in a limited space and must be small in size and light in weight, that is, lightweight. But at the same time, the robot’s high load, high rotation accuracy, high running stability, high positioning speed, high repeat positioning accuracy, long life, and high reliability performance require that the supporting robot bearings must have high load carrying capacity, high precision and high performance. Stiffness, low friction torque, long life, high reliability performance. Lightweight and high performance are a contradiction.

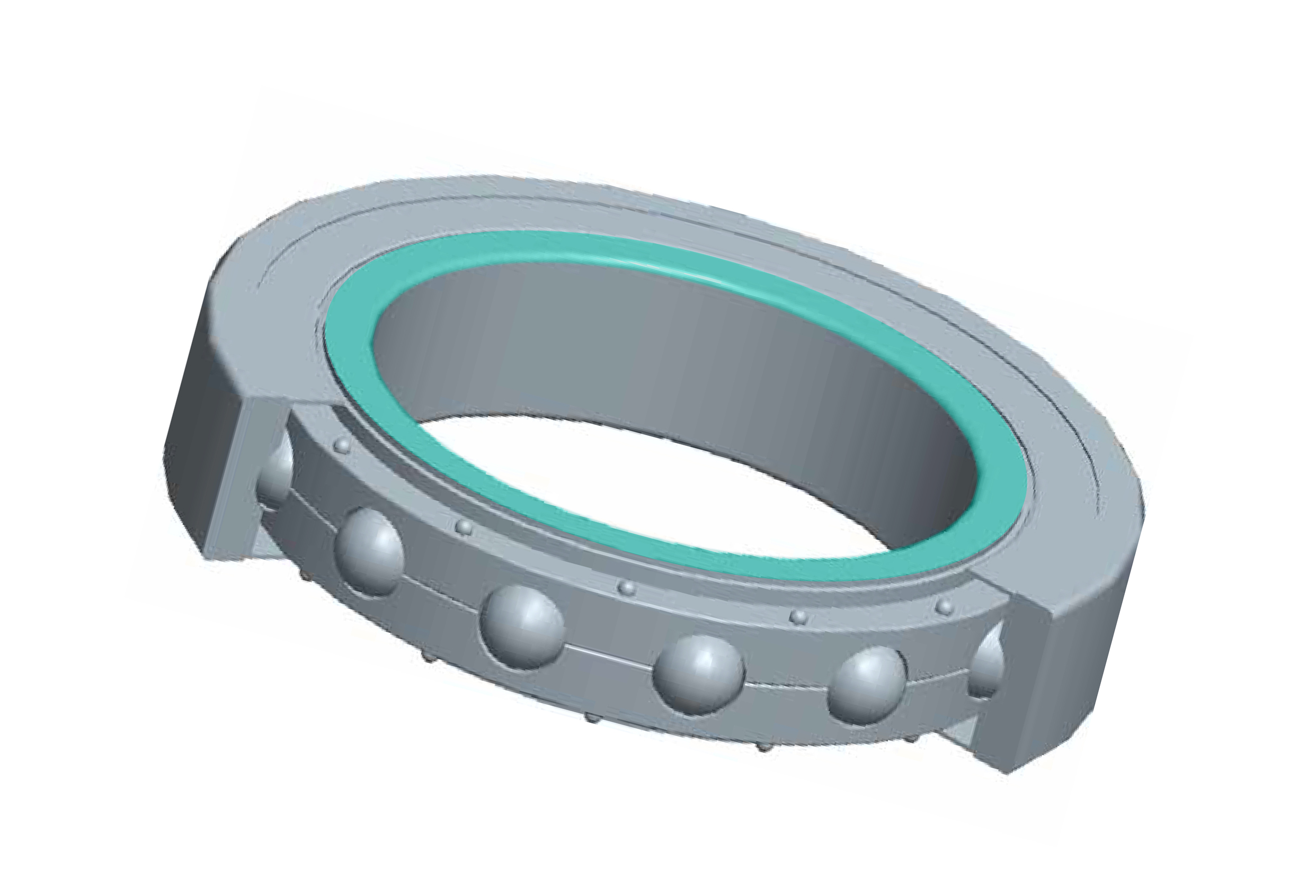

Industrial robot bearings, as one of the key components of industrial robots, mainly include two types of bearings for industrial robots, one is a uniform cross-section thin-walled bearing, and the other is a cross-roller bearing. In addition, there are harmonic reducer bearings, linear bearings, joint bearings, etc., but the main ones are equal-section thin-wall bearings and cross-roller bearings.

-

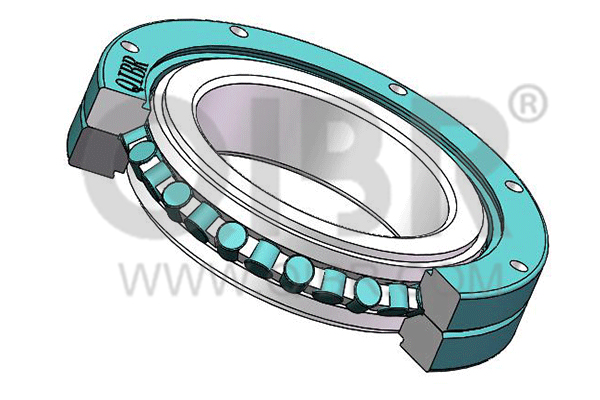

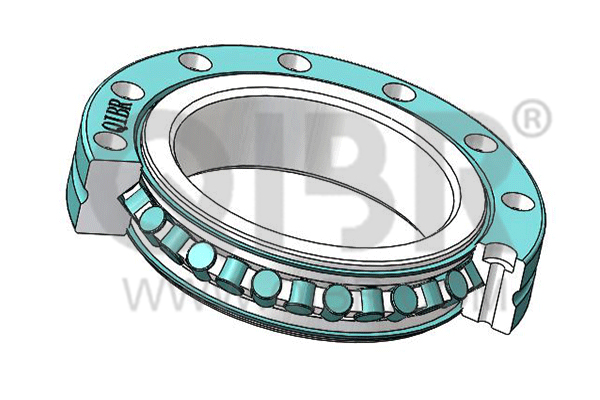

Cross roller ball bearing

-

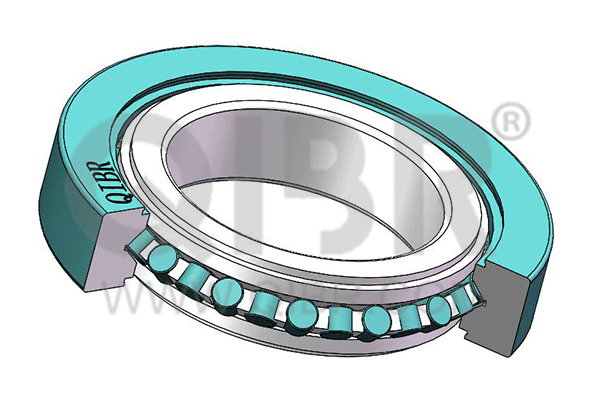

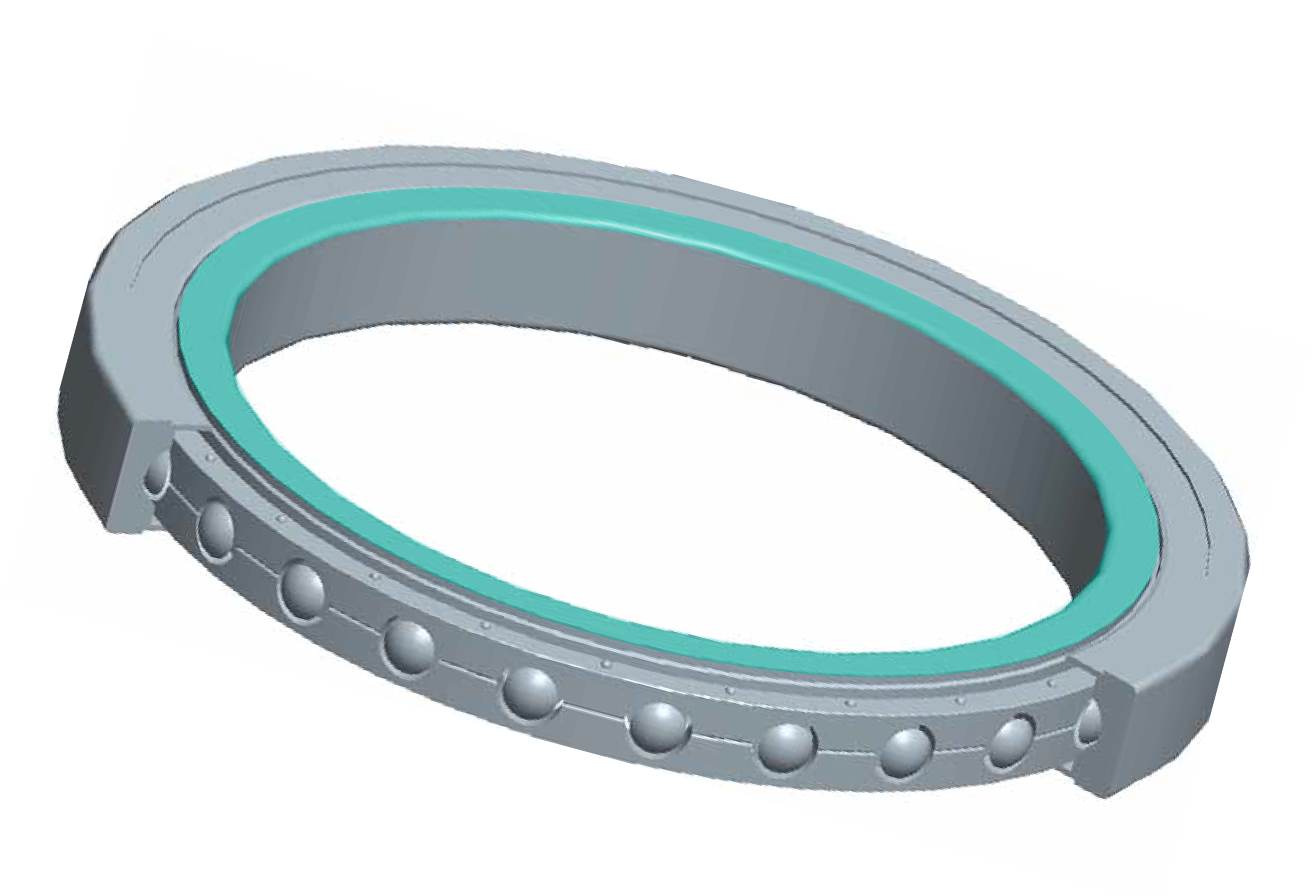

Thin section ball bearing