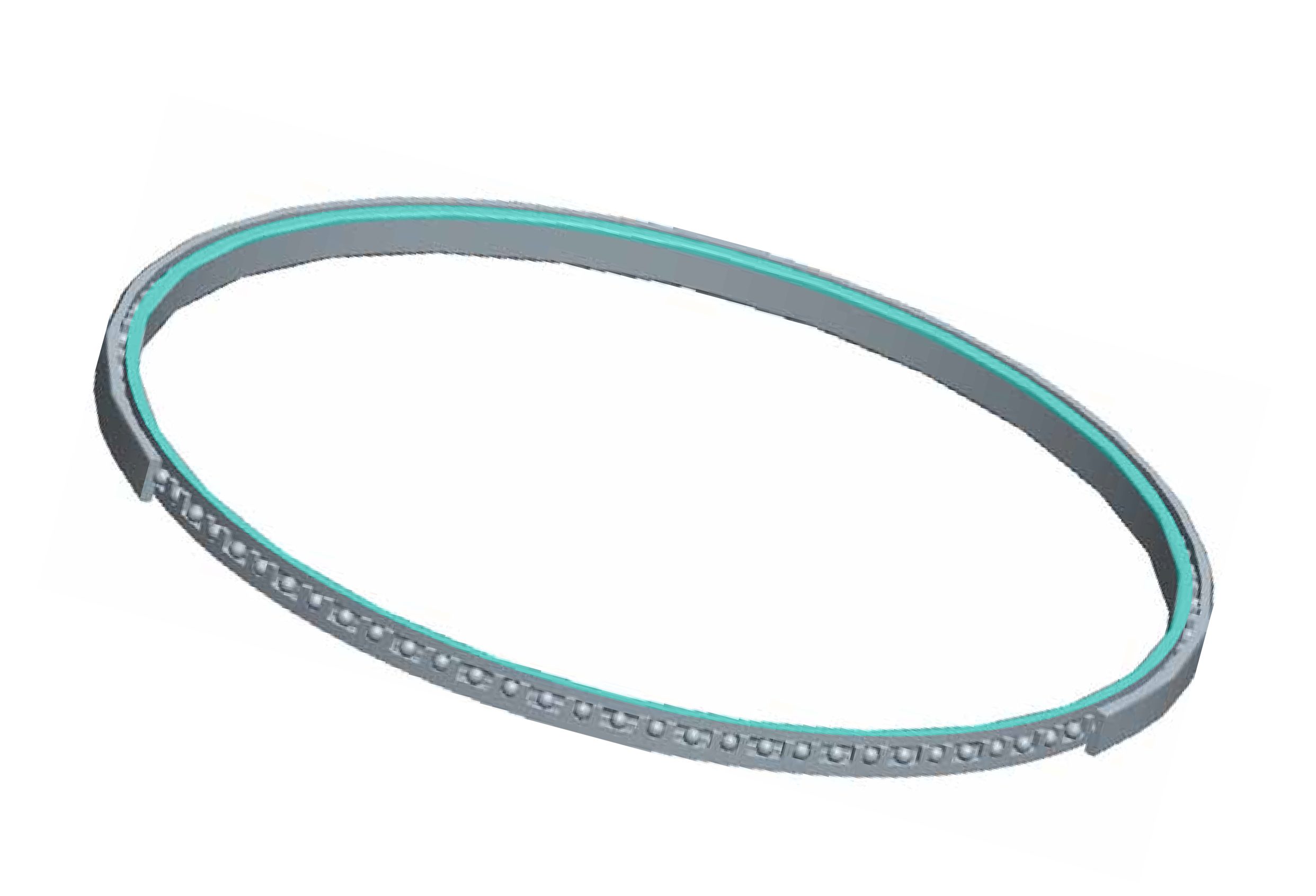

The thin section of ultra-thin-walled bearings is very popular in many industries. Therefore, more and more ultra-thin-wall bearings are chosen to be used in robot joints, precision instruments, medical equipment and other fields. We may encounter the fracture of the bearing inner ring or the bearing outer ring during use. Today we will analyze the specific reasons.

1. The problem of bearing forgings.

2. The heat treatment causes the carbide particles to be large, and metallographic analysis of the ferrule can be carried out.

3. Excessive stress or abnormal knocking during bearing installation may cause cracks in the ferrule. After a period of use, the cracks will spread and cause damage.

4. The bore of the bearing seat is too large, and the clearance of the outer ring of the bearing is large. Subject to impact while working.

5. Poor dynamic balance, resulting in large cyclic stress in a local area of the cross-sectional surface of the heavy end of the bearing, where fatigue is faster, and cracks will occur after a certain period of time, resulting in fracture.